Your Files Are Being Processed

Please Wait

Aaron Video

Contact Aaron

Contact Information

Phone: 630-350-2200

Toll Free: 1-800-49-AARON

Email: [email protected]

Cart

View Your Price Quote

- Make sure all words are spelled correctly.

- Try different keywords.

- Try more general keywords.

-

{{#each productSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each contentSuggestedQueries.results}}

- {{query}} {{/each}}

-

{{#each categories.results}}

- {{html title}} {{/each}}

-

{{#each content.results}}

- {{html title}} {{/each}}

-

{{#each queries.results}}

- {{query}} {{/each}}

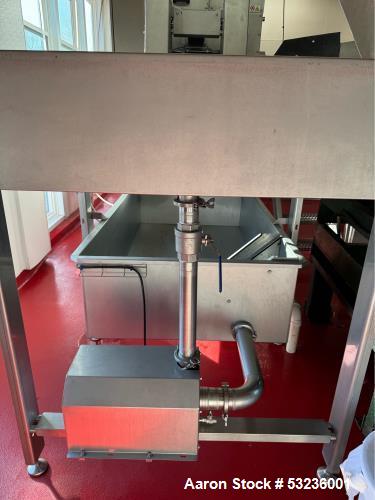

Used ABL PDS TT 50 Apple Peeler Corer – Stainless Steel, 250-500 kg/hr Capacity

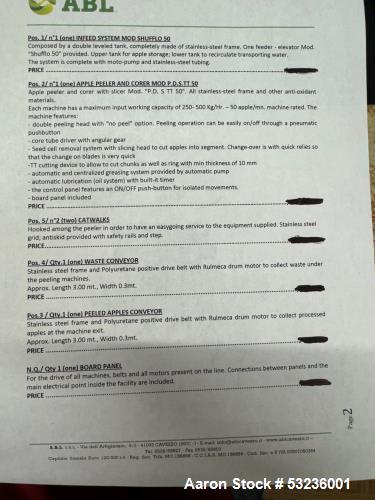

Used ABL PDS TT 50 Apple Peeler Corer. All stainless steel. Capacity 250-500kg/hr, - 50 apple/mn. Infeed system Mod Shufflo 50 Double peeling head with "no peel" option, core tube driver with angular gear, seed cell removal system with slicing head to cut apples into segment. TT cutting device to allow to cut chunks as well as ring with min thickness 10mm. Auto grease and lube system. Includes (2) catwalks, waste conveyor, (1) peeled apple conveyor and control panel.

| Model | PDS TT50 |

| Category | General EquipmentGeneral Equipment |

| Subcategory | General EquipmentGeneral Equipment |

Manufacturer Information:

- Manufacturer: ABL

- Model: PDS TT 50

- Condition: Used

Description:

The ABL PDS TT 50 Apple Peeler Corer is a high-capacity industrial apple processing machine, designed for automated peeling, coring, and slicing. Constructed from stainless steel, this unit is built for food-grade processing applications and ensures hygienic and efficient operation.

With a processing capacity of 250-500 kg/hr (50 apples per minute), this system features an infeed system with a Mod Shufflo 50, a double peeling head with a "no peel" option, and a core tube driver with an angular gear for precise coring. The seed cell removal system and slicing head allow apples to be cut into segments, chunks, or rings (minimum thickness: 10mm), providing versatility for different food production needs.

The TT cutting device enables customized cuts for chunks and rings, while the auto grease and lubrication system ensures smooth operation with minimal maintenance. The unit includes:

- (2) Catwalks for easy access

- Waste conveyor for peel and core removal

- Peeled apple conveyor for streamlined product transport

- Control panel for automated operation

This fully automated apple processing machine is ideal for high-volume food production, improving efficiency, accuracy, and product consistency.

Specifications:

- Model: PDS TT 50

- Material: Stainless Steel

- Processing Capacity: 250-500 kg/hr (50 apples per minute)

- Peeling System: Double Peeling Head with "No Peel" Option

- Coring System: Core Tube Driver with Angular Gear

- Seed Removal System: Integrated

- Cutting System:

- Slicing Head for Segment Cutting

- TT Cutting Device for Chunks & Rings (Min Thickness: 10mm)

- Lubrication System: Auto Grease & Lube System

- Included Components:

- (2) Catwalks

- Waste Conveyor

- Peeled Apple Conveyor

- Control Panel

- Condition: Used

Applications:

The ABL PDS TT 50 Apple Peeler Corer is ideal for:

- Food Processing & Manufacturing

- Apple Slicing & Peeling for Retail and Commercial Use

- Pre-Cut Fruit Production

- Apple Processing for Juices, Pies, and Snacks

- Cider & Applesauce Manufacturing

What Products Would This Be Used For?

- Pre-sliced apple products

- Apple rings and chunks

- Apple-based desserts and snacks

- Dried apple processing

- Apple sauce, cider, and juice production

Apple Coring, Apple Slices, Apples, Food Industry, Food Processing, Food Production, Food Products, Food Specialty Ingredients, Foods, Fruit, Fruit Peeling, Fruits

- Apple peeler corer

- ABL apple processor

- Industrial apple peeler

- Fruit processing machine

- Automatic apple slicer

- Used ABL PDS TT 50 apple peeler corer

- High-capacity industrial apple processing machine

- Automatic apple peeler with slicing and coring system

- Stainless steel apple processing equipment for food production

- Peeling, coring, and slicing machine for commercial apple processing

- Used ABL PDS TT 50 apple peeler corer with 250-500 kg/hr capacity

- Automatic industrial apple processing machine for peeling, coring, and slicing

- High-speed apple peeling and slicing system with waste conveyor and control panel

- Stainless steel fruit processing machine with TT cutting device for apple chunks and rings

- Commercial apple processing equipment with auto lubrication and grease system

"Dealing with Aaron is an easy and enjoyable process"

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

"This is my first time using Aaron Equipment to purchase equipment. They were easy to work with and things were done quickly and efficiently. I will be a repeat customer when the need arises. This is a trustworthy company that delivers what they advertise."

"I have purchased multiple pieces of equipment through Aaron equipment over the past 15 years. The staff has been very knowledgeable on every request & have spent countless hours ensuring that the equipment I was purchasing met my expectations."

"I have been doing business with Aaron equipment for many years. This year I had the need for some used equipment in a new business Venture. I got in touch with Ryan Davies. I could not be happier with the response and honesty exhibited by him. Dealing with them was a pleasure and everything was as represented. Fair an Honest is how I would describe them."

“Aaron Equipment was very easy to get into contact with and get a price on a un-used chiller they were selling. The process was seamless and very easy on our end and we had the equipment much faster than going out for bid on it to multiple vendors and we able to come in under budget on the project.”

"Aaron Equipment is always my first call for used process equipment. Their inventory and customer service has ensured successful project results every time. Thanks y’all!"

"I have purchased all different types of equipment from Aaron Equipment over the last 10 years and have always been 100% happy with not only the equipment but with their customer service!"

"Working with Aaron Equipment Company was as easy as it gets."

"It is a pleasure to work with AEK and I would recommend them as an equipment supplier."

"The partnership we enjoy with Aaron has helped our business to be what it is today – thank you guys!”

"I will definitely use Aaron Equipment in the future."

"Aaron’s customer service indicates that they want long term partnerships and that is something we especially appreciate."

"I really value shopping for used equipment from Aaron Equipment Company because the information they present is accurate, their prices fair and their customer service is the best…Highly recommend."

Used ABL PDS TT 50 Apple Peeler Corer. All stainless steel. Capacity 250-500kg/hr, - 50 apple/mn. Infeed system Mod Shufflo 50 Double peeling head with "no peel" option, core tube driver with angular gear, seed cell removal system with slicing head to cut apples into segment. TT cutting device to allow to cut chunks as well as ring with min thickness 10mm. Auto grease and lube system. Includes (2) catwalks, waste conveyor, (1) peeled apple conveyor and control panel.

Manufacturer Information:

- Manufacturer: ABL

- Model: PDS TT 50

- Condition: Used

Description:

The ABL PDS TT 50 Apple Peeler Corer is a high-capacity industrial apple processing machine, designed for automated peeling, coring, and slicing. Constructed from stainless steel, this unit is built for food-grade processing applications and ensures hygienic and efficient operation.

With a processing capacity of 250-500 kg/hr (50 apples per minute), this system features an infeed system with a Mod Shufflo 50, a double peeling head with a "no peel" option, and a core tube driver with an angular gear for precise coring. The seed cell removal system and slicing head allow apples to be cut into segments, chunks, or rings (minimum thickness: 10mm), providing versatility for different food production needs.

The TT cutting device enables customized cuts for chunks and rings, while the auto grease and lubrication system ensures smooth operation with minimal maintenance. The unit includes:

- (2) Catwalks for easy access

- Waste conveyor for peel and core removal

- Peeled apple conveyor for streamlined product transport

- Control panel for automated operation

This fully automated apple processing machine is ideal for high-volume food production, improving efficiency, accuracy, and product consistency.

Specifications:

- Model: PDS TT 50

- Material: Stainless Steel

- Processing Capacity: 250-500 kg/hr (50 apples per minute)

- Peeling System: Double Peeling Head with "No Peel" Option

- Coring System: Core Tube Driver with Angular Gear

- Seed Removal System: Integrated

- Cutting System:

- Slicing Head for Segment Cutting

- TT Cutting Device for Chunks & Rings (Min Thickness: 10mm)

- Lubrication System: Auto Grease & Lube System

- Included Components:

- (2) Catwalks

- Waste Conveyor

- Peeled Apple Conveyor

- Control Panel

- Condition: Used

Applications:

The ABL PDS TT 50 Apple Peeler Corer is ideal for:

- Food Processing & Manufacturing

- Apple Slicing & Peeling for Retail and Commercial Use

- Pre-Cut Fruit Production

- Apple Processing for Juices, Pies, and Snacks

- Cider & Applesauce Manufacturing

What Products Would This Be Used For?

- Pre-sliced apple products

- Apple rings and chunks

- Apple-based desserts and snacks

- Dried apple processing

- Apple sauce, cider, and juice production

Apple Coring, Apple Slices, Apples, Food Industry, Food Processing, Food Production, Food Products, Food Specialty Ingredients, Foods, Fruit, Fruit Peeling, Fruits

| Model | PDS TT50 |

| Category | General Equipment |

| Subcategory | General Equipment |

- Apple peeler corer

- ABL apple processor

- Industrial apple peeler

- Fruit processing machine

- Automatic apple slicer

- Used ABL PDS TT 50 apple peeler corer

- High-capacity industrial apple processing machine

- Automatic apple peeler with slicing and coring system

- Stainless steel apple processing equipment for food production

- Peeling, coring, and slicing machine for commercial apple processing

- Used ABL PDS TT 50 apple peeler corer with 250-500 kg/hr capacity

- Automatic industrial apple processing machine for peeling, coring, and slicing

- High-speed apple peeling and slicing system with waste conveyor and control panel

- Stainless steel fruit processing machine with TT cutting device for apple chunks and rings

- Commercial apple processing equipment with auto lubrication and grease system

We pay "Top Dollar" for your idle process equipment! Fill out our form and our buying team will get back to you.

SELL YOUR EQUIPMENTView our entire process equipment inventory online or visit our location for an equipment inspection.

View Inventory